ALTERNATIVE MATERIALS TO PLASTIC. The attention to the environment becomes law.

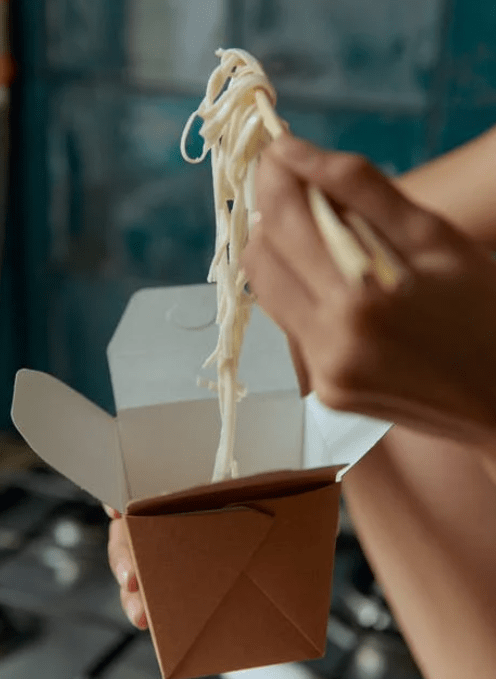

The restaurant owner has to adjust his warehouse stock to the take-away containers in biodegradable materials.

How to get oriented?

The study of innovative materials has led to the discovery of valid materials substitutes for plastics. Once identified as alternatives, it is necessary to introduce them into their own management software.

For the transport of cold food containers are available in IngeoTM (P.L.A.), for hot drinks the P.L.A. Crystallized in lids, plates and containers with lid and some types of glasses of the cellulose pulp.

Alternative materials to plastic

The study of alternative materials to plastic and innovative has led to the discovery of valuable materials substitutes to plastic.

With the discovery of new materials, alternatives to plastic have been invented. These alternative and innovative substitutes will also help the environment by being eco-friendly

In recent years there has been an increase in the study of various types or compounds to be used instead of this material that causes pollution if not handled properly One of these substitutes is polyurethane that can take any desired shape unlike other plastics because it is flexible but durable!

Once identified as alternatives it is unwise to introduce them in your management software.

Alternative materials to plastic

Let’s see the technical features.

ALTERNATIVE MATERIALS TO PLASTIC

IngeoTM (P.L.A.) is a family of bio polymers deriving from corn starch, completely biodegradable and composed according to EN 13432. The amorphous polymer resists a maximum temperature of 45 ° C and is perfectly transparent.

Ingeo ™ is mostly used in therm forming, to produce glasses and trays with aesthetic and mechanical characteristics similar to polystyrene but, given its low resistance to high temperatures, suitable only for beverages and cold food.

Transparent, with hermetic closure and in the three small, medium and large sizes, they resist up to a maximum temperature of 45 °.

For the production of cups for hot drinks, the P.L.A. Crystallized.

Crystallization is a process that makes P.L.A. (originally amorphous) able to withstand higher temperatures up to 85 ° C. Exactly like the PLA bio polymer from which it derives is biodegradable and composed according to EN 13432. Once crystallized, the CPLA loses its original transparency and becomes milky white.

For hot food there are containers with hinged lid in cellulose pulp, both in the mono-compartment version, both in the two- and three-compartment versions.

The cellulose pulp is obtained from waste processing of fast-growing plants, especially sugarcane, bamboo or straw, and is therefore entirely made of natural materials, as well as being completely biodegradable and composed according to EN 13432. The pulp is white and resists up to a maximum temperature of 100 ° C.

Suitable for microwave and traditional oven. It is mainly used for the production of plates and containers with lid but it is also used for some types of glasses.

They are made of cardboard coming from responsibly managed forests, covered with a Mater-Bi film that ensures the tightness of liquids – hot and cold – and the suitability for contact with food.

What is that? MATER-BI is a completely biodegradable and composed bio-plastic family with which solutions and products with reduced environmental impact are realized for everyday life.

Card + Mater-Bi®: it is a cardboard made of fibers from responsibly managed forests. The inner side, in contact with food, has a Mater-Bi® coating that guarantees its resistance to liquids and the suitability for contact with food up to a maximum temperature of 70 ° C.

Carton board: it is made of fibers from responsibly managed forests. If it is also Bio Coated, it means that it has undergone a mechanical surface treatment that makes it more resistant to temperature, liquids and fats.

Read also: Takeout containers: towards the prohibition of plastics in 2021